Pharmaceuticals Industry

Why do we recommend you select airless pump bottles for your pharmaceutical products?

Airless Pump Bottle Packaging in Pharmaceauticals

Airless pump bottle packaging protect sensitive products such as natural skin care creams, serums, foundations, and other preservative-free formula creams by preventing them from excessive exposure to air, thus extend the product shelf life.

What can we do for your pharmaceutical jar and bottle packaging?

Color Coating

Any Pantone code color into reality. Matte surface, Frosted & Glossy finish, Metallic coating, Gradient colors, which are in transparent seeing-through or opaque effect.

Brand Printing

Shaoxing CosPack provides different printing for option. Silk-screen Printing, Foil Hot-stamping, 3D Printing, Heat-transfer Printing, Pad Printing, label and much more.

Box & Bags

One-stop packaging solution premium service. Help you source the suitable secondary packaging such as sticker, box, gift packaging, bag and other packaging.

Ideal Pharmaceutical Packaging

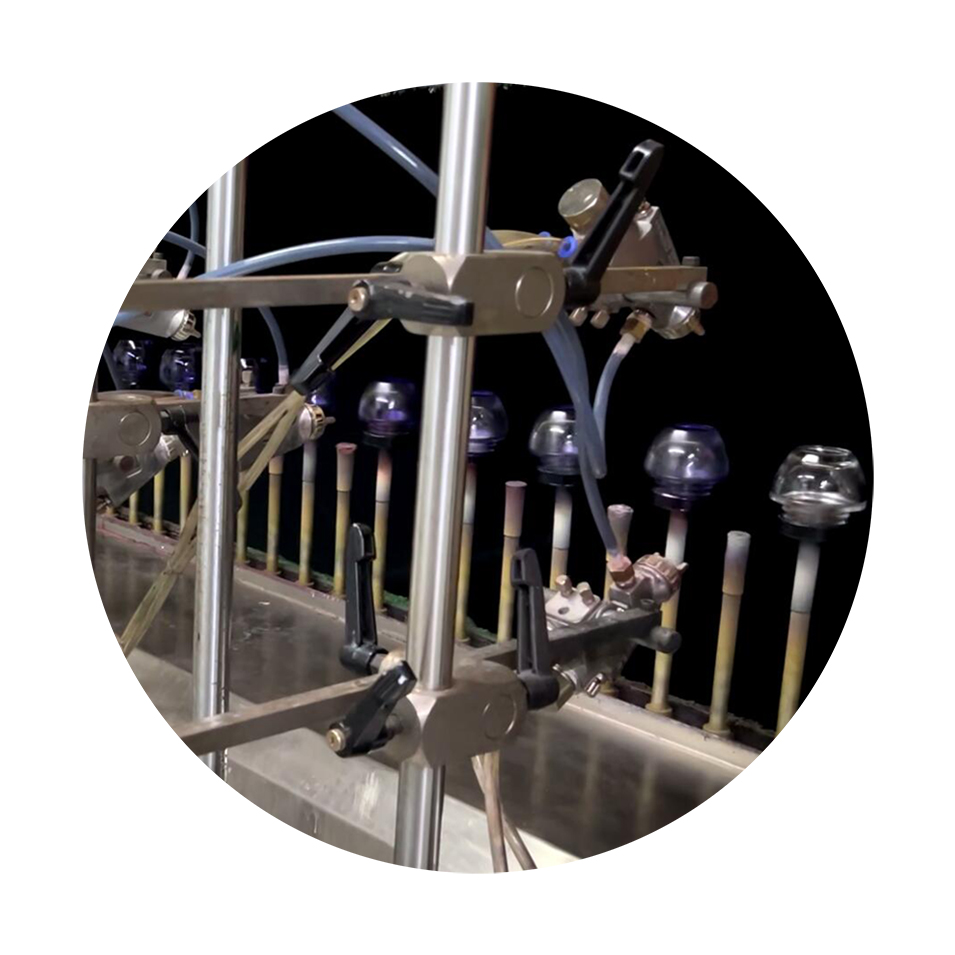

- Airless Dispensers on the market -

How to use airless bottle correctly and how to address the problem you probably have met? Watching the video promptly!

Airless Cream Jar & Serum Dispenser Packaging

Airless pump jars and bottles are workable in vacuum environment without air so as to keep the active ingredient of skin care products not easy to be oxidation. Customized coloring and branding for option.

Unlimited Customized Airless Containers

Providing bespoke solution from coloring, branding, labeling and more, make your products more excellent and personalized, let customers remember your products and your brands better.

How to achieve your custom skin care packaging?

Learning our full processing procedures from prototype bottle manufacturing to custom coloring and printing process, Inspection & Packing ready to ship.

Prototype Bottle Manufacturing

Painting Color Process

Pantone Code Reference

It is universal Color Standard and provides color mixed matching reference. Avoiding effectively to see different in the different displays.

Printing Process

Our printing specialists make your designs into the physical samples efficiently and accurately by semi-auto & full-auto printing machines.

Quality Control Test

QC covers the full manufacturing procedures and application. Such as the appearance, function test, leakage test, torque, filling and much more.

Reliable Skincare & Cosmetic Packaging Supplier

We address custom skin care containers not only those who deal in small personalized business, but also those who have large purchasing requirement. By selecting a wide variety of inventory bottles, we can provide customized printing service. Regarding to the large order, it is easier to process OEM bottles by custom coloring and branding services. Supporting your brand’s goal for ongoing and the future, which helps your business grow continuously. Becoming your trustworthy supplier and partner is our unwavering commitment.